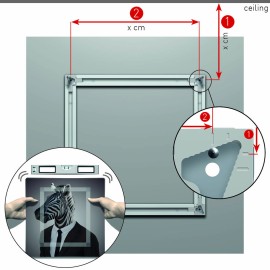

Connecting the profile parts is easy. Press the corner connector into a profile part until the straight surfaces of the profile and the corner connector are closely aligned. Then you do the same action with the next profile part.

If the connection is not entirely successful, do not use any hard tools to achieve your goal. A small rubber mallet is sufficient for a good closure. Perhaps unnecessarily, it is important to make sure that the correct lengths are connected.

Continue in this way until a U-shape is formed. You can now place the two remaining slide-in corner connectors in the remaining profile at the same time and then connect it to the existing U-shape so that a solid frame is created.

The "flat" surface of the molded plastic insertion corner has a unique combination of curves to create a slightly concave surface on the bonding surface. This minimizes the risk that the sharp corner of a miter frame will cause a bump on the front of the panel when bent.